The selection of flexible packaging for modern business markets creates significant performance benefits. The selection process extends beyond product containment since it safeguards your items and strengthens your brand reputation while saving financial resources. Every business operating within the food or beauty sectors requires a proper decision process for selecting flexible packaging solutions.

The following post analyzes essential elements you should evaluate. The article provides a comprehensive discussion about packaging material choices and sustainable solutions, as well as supplier stability analysis and cost structure evaluation, and upcoming industry trends. This guide will assist you in making a choice that beats the competition.

1. Understand Your Product’s Needs

Your first step should be to determine what your product requires from packaging.

Protection & Shelf Life

Think about your product’s fragility. Does it need extra cushioning? Food products should receive packaging solutions which maintain shelf stability through the exclusion of oxygen and moisture. The implementation of appropriate packaging methods minimizes food waste through means of up to 20%.

Packaging Material Compatibility

Your product’s dimensions, weight, and sensitivity matter. When packaging perishable food items, you should choose solutions that extend shelf life.

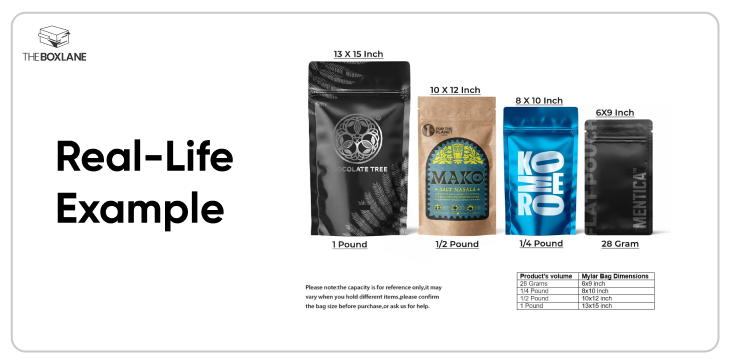

Real-Life Example

An illustration of a small juice business producing organic beverages would be appropriate. The company required packaging that preserved their product quality without introducing any preservatives. Flexibility in packaging selection with films manifesting high barriers led to a 30% shelf life enhancement, besides minimizing spoilage occurrences.

Keep your product requirements clear. The information you gather at this point will help you proceed toward selecting flexible packaging.

2. Material Selection and Sustainability

Selecting the appropriate material stands as a critical decision. Performance quality and brand environmental impact become directly affected by this decision.

Compare Materials

Your selection should include examination of plastics alongside laminates and biodegradable films, and additional materials. The selection of correct packaging materials results in decreased expenses and waste production, according to research.

Sustainable Packaging

Today, consumers care about eco-friendliness. The packaging you seek must be environmentally friendly and both recyclable and made from recycled materials. Some companies implement bio-based films, which serve as product protection while cutting down their carbon emissions.

Real-Life Example

The large snack company adopted biodegradable laminate materials to use in its pouch packaging. This change resulted in better environmental standings for the company while delivering improved product preservation. The Sustainable Packaging Coalition provided research backing their transition to sustainable packaging.

Tip:

Find comprehensive guides and case studies regarding the selection of the right flexible packaging materials by typing “how to select the right flexible packaging materials” into search fields.

3. Cost and Logistics Considerations

The overall cost includes more than basic material expenses. The cost comprises all aspects of delivery as well as management and distribution requirements.

Cost-Effective Packaging

Transportation expenses decrease because of the weight reduction brought by flexible packaging. The package weight directly affects fuel usage.

Packaging Cost Analysis

Consider the full life cycle. High-quality packaging that costs slightly more may prove beneficial because it decreases product losses, thus saving money in the long term.

Packaging Logistics

Assess where the packaging exists in your operational processes. Products distributed across the whole country can benefit from using durable lightweight material, which decreases shipping expenses.

Real-Life Example

By using a flexible pouch, the cosmetics company lowered its delivery expenses by 15%. The new solution demonstrated how choosing the right flexible packaging would generate important savings in logistics operations.

4. Branding, Design, and Consumer Appeal

Customers will first encounter your packaging when they view your products. Your brand should appear through the packaging, while it must appeal to customers.

Packaging Design

Companies can create unique packaging solutions that distinguish their products in the market. The design needs to use vibrant printing together with innovative shapes in order to capture consumer attention.

Brand Packaging Impact

The features you should consider include resealability and easy opening, together with a distinctive texture. The addition of such details creates a superior user experience, which develops brand loyalty.

Consumer Packaging Trends

Research indicates that customers progressively choose packages that present a personal touch alongside sustainable elements. Nielsen research reveals that 66% of consumers show a willingness to spend additional money on packaging that has environmentally friendly characteristics.

Real-Life Example

A rising food business applied contemporary functional packaging alterations into its design while integrating reseal capabilities. Through this improved packaging design, the company achieved both higher self-optimization on store shelves, together with a 25% rise in consumer return purchases.

5. Supplier Reliability and Support

A supplier's inability to deliver packaging products makes any form of packaging ineffective.

Choosing a Packaging Supplier

Select suppliers who maintain an honorable reputation combined with a history of successful operations. The supplier must provide both adjustable manufacturing schedules and personalized packaging solutions to their clients.

Supplier Reliability in Packaging

The packaging partner needs to provide assistance starting from the design phase all the way to manufacturing. The supplier should provide assistance with all tasks including design changes along with compliance requirements.

Real-Life Example

A mid-sized beverage company formed a business connection with a neighborhood supplier who stood out for their outstanding customer service. Thanks to their special collaboration the company gained speed in order adjustments along with design innovations which helped them retain their competitive edge.

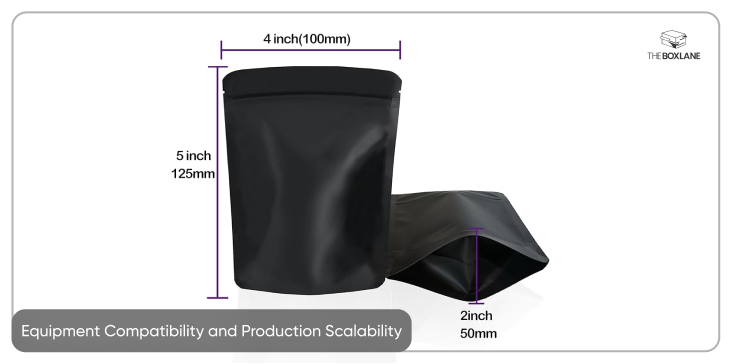

6. Equipment Compatibility and Production Scalability

The production line you currently use demands that your packaging selection conforms to its existing setup.

Production Scalability

Your business expansion will influence the requirements for your packaging. Your choice of flexible packaging must offer scalability features.

Packaging Material Selection

Verify that the selected material works with all equipment used for filling, sealing, and printing operations. Production delays, together with increased costs, occur when packaging materials fail to be compatible.

Real-Life Example

The dairy product company implemented flexible pouches, which integrated perfectly with their automated filling systems. The implementation of this change enabled machines to operate 20% faster while decreasing operational interruptions.

7. Regulatory Compliance and Food Safety

Food and beverage companies need to keep regulatory standards because compliance regulations is mandatory.

- Food Contact Materials:

The selected packaging materials must comply with every requirement in food safety regulations. The packaging material needs to have official certifications along with testing reports to prove its appropriateness. - Packaging Safety:

The protective measures implemented for consumers through proper packaging standards help prevent instances of costly product recalls, together with possible legal problems. - Real-Life Example:

The premium organic food brand selected FDA-approved material for its food packaging. The safety standards of their packaging choice guaranteed both consumer safety and brand reputation enhancement.

Emerging Trends and Future Innovations

The key to competitive advantage lies in monitoring the most recent trends happening in flexible packaging.

- Smart and Active Packaging:

Recent technological developments in packaging systems transform this packaging method from an item that protects products to an additional functional capability. Several packages have developed abilities to track freshness levels while showing changing visual elements. - Digital Printing Innovations:

Digital printing technologies allow businesses to develop personalized designs and run them at reasonable production costs. - Consumer Behavior Trends:

People today prioritize products that give them convenient solutions as well as environmentally friendly approaches. Your product will gain improved market competitiveness when you follow current packaging trends that consumers care about. - Real-Life Example:

A major company in the health food industry introduced its product line with smart packaging features. The packages from this company displayed information about the approaching expiration date of their products. The new packaging innovation successfully attracted health-sensitive customers, which resulted in a 30% boost in market purchases.

Final Thoughts

Your business will encounter multiple stages during the selection process of flexible packaging solutions which impact every operational aspect. All business decisions matter when you need to understand specific product demands while achieving sustainable packaging that meets logistics needs.

Your product requirements must be defined before moving forward. Review packaging material selection guides and perform research to discover extension-resistant materials that also minimize waste. You should consider logistics together with cost elements to get efficient packaging solutions. Design your packaging with the purpose of advancing your brand presence while conforming to current packaging preferences among consumers.

Your company should work with an established packaging supplier that provides customized solutions and support. Your packaging must be verified to perform well with production tools and grow with your business expansion plans. The last principle is to always adhere to both safety regulations and food safety rules.

Proper selection of flexible packaging brings forth multiple advantages that become evident. Your business will achieve waste reduction along with cost savings and brand image enhancement while creating delighted customers. These seven factors guide brands of all sizes to develop exceptional packaging solutions that catch consumer attention in the market.

Your packaging journey is about to reach its highest point. The guide serves as your reference document. Begin by assessing different options, then ask relevant questions before teaming up with experts to achieve success. Right flexible packaging functions beyond its basic role as a container since it serves as an essential business growth tool.

A packaging solution that operates with the same efficiency as your business can be achieved through an assessment of product requirements and material durability and costs together with design creativity and supply chain management and manufacturing expansion potential and regulatory adherence.

Take action today. Review your current packaging. Explore new trends and technologies. Link up with a reliable supplier who fully grasps your business goals. Your product needs the best packaging solution because flexible packaging selection leads your brand to enduring success.