You might be surprised to learn that 79% of all products transported internationally are packed in corrugated boxes. Being an entrepreneur, the significance of this packaging type can greatly influence your business. As e-commerce is growing year by year and expected to reach $6.3 trillion in 2024, selecting the correct packaging is vital for the product quality and customer experience.

Corrugated boxes are not just protective packaging materials, they are tools for branding, sustainability and cost effective solutions. Not only are these boxes lightweight but also strong enough to protect the product during shipping and enhance the unboxing experience for clients.

In this guide, we will review all the features of corrugated boxes, including their structures and types and the advantages of using them and their environmental impact. It’s important to understand corrugated packaging if you are in the retail, logistics or manufacturing industries as it will assist you to save time and money. Now let’s take a closer look at corrugated boxes and see how they can help your business grow!

1. What Are Corrugated Boxes?

Corrugated boxes are made from linerboard and fluting which is a wavy layer inserted between two flat liners. This special type of construction makes corrugated boxes strong and rigid, they are normally used in carrying and storing goods. While normal cardboard boxes are made only out of a single layer of paper, corrugated boxes have been specially developed with pressure and impact in mind thus guaranteeing the contents’ safety during transport.

The Structure of Corrugated Boxes

- Linerboard: The outer layers that give the structure and also can be used for printing.

- Fluting: The second layer from the center that has a wavy pattern for padding and rigidity.

- Types: Depending on the number of fluted layers, corrugated boxes are divided into single-wall, double-wall and triple-wall boxes.

2. Types of Corrugated Boxes

It is important to have an insight on the various types of corrugated boxes so as to determine which is best suited to a certain application. They each possess characteristics that make them suitable for certain uses.

Single-Wall Boxes

Single-wall boxes have a single fluted medium placed between two outer skins, also known as linerboards. They are cheap and easy to handle, and therefore they are suitable for use in transporting small and delicate products such as textiles, books and other non- breakable products.

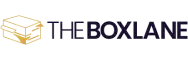

Double-Wall Boxes

Double-wall boxes are built with two layers of fluting and three linerboards increasing the boxes’ strength and sturdiness. It is ideal for transporting ‘’bulky’’ loads including electronics and glass products.

Triple-Wall Boxes

Triple wall boxes have three plies of fluting as indicated in their name and four liner boards. These boxes are very sturdy and are meant for the heaviest loads, like machinery and industrial equipment.

Specialty Boxes

Apart from standard boxes, there are also some special types of boxes such as die cut and foldable to fulfill specific requirements. Die-cut boxes can be made according to the shape of the product, whereas foldable boxes can store and ship the product easily.

3. Advantages of using Corrugated Packaging

Corrugated packaging has many benefits which make it to be a preferred packaging material among many companies.

Strength and Durability

Due to its construction, corrugated boxes are quite strong; therefore, they cannot be easily crushed, pierced or torn. Smithers Pira has estimated that the global corrugated packaging market is projected to touch about $300 billion by the year 2025 further proving the need for stong packaging.

Lightweight Yet Robust

Corrugated boxes are very strong and yet very light making it possible to cut down on the cost of shipping. This characteristic is particularly helpful for e-commerce companies to save money on equipment and keep their products safe.

Cost-Effectiveness

Corrugated boxes are affordable than many other types of packaging especially if you are ordering large quantities at a time. Light weight is also an advantage in transportation costs hence making it affordable for companies to use in their operations.

Customization Options

Corrugated boxes are easy to customize with printing and design making it possible for businesses to enhance branding. The customized boxes can be designed with logos and product information that will help to attract clients and create avenues for brand equity.

Recyclability and Eco-Friendliness

All corrugated boxes are manufactured from natural resources and are 100% recyclable. This is in line with rising customer preferences for eco-friendly packaging. A survey carried out in the recent past revealed that consumers care more about brands that make use of environment friendly packages.

4. How to Choose the Right Corrugated Box

When choosing the right corrugated box for your needs, make sure to consider the following factors:

Weight and Dimensions

Determine the size as well as the weight of your product and then settle on the right box that is strong enough to hold the product. Also, use the dimensions of your item to make certain that the size fits your item perfectly. A box with a large size may result in movement and subsequent breakdown during transportation.

Type of Contents

Think about what type of product you are sending out. Delicate goods need extra protection and a thicker carton, while low density products can be packed in single wall containers.

Cushioning and Internal Packing Materials

Sometimes, you might be required to pack extra cushions like bubbles or foam to avoid physical injury to the stuff. Make sure the internal material can fit the box as it is designed.

5. The Manufacturing Process of Corrugated Boxes

In order to find the quality and reliability of the corrugated boxes, you need to know how they are manufactured.

Raw Materials

The main inputs in corrugated boxes production are recycled paper and wood pulp. Recycling is getting more popular as organizations embrace sustainability goals, and recycled material usage is widespread.

Production Steps

Sheet Formation

The slurry is then turned into sheets of paper.

Fluting Production

The fluted layer is made by running sheets through corrugating rolls.

Lamination

The fluting is located in between two linerboards.

Die-Cutting and Printing

Boxes are trimmed and labeled according to the specific requirement.

Quality Control

Companies continue to exercise high levels of quality control to guarantee that a box is of optimum quality. Some of the tests conducted on this material include the compression strength, the moisture and general sturdiness test.

6. Eco-Friendly Corrugated Boxes

As people become more sensitive to the environment, more companies are looking for sustainable methods of packaging, and corrugated boxes are ideal.

Sustainable Sourcing

Most of the materials used by manufacturers are obtained from well managed forests. Bodies such as FSC stand for the certification of paper products to ensure that the raw material used in production is obtained sustainably.

Benefits of Recycled Materials

Recycled paper not only shows strength in waste management but also decreases the carbon dioxide emissions during paper production. Research has shown that up to 60% of energy used in the process of making new paper can be conserved when recycled paper is used.

Recycling for the Environment

Used corrugated boxes are supposed to be returned for recycling by the consumers. Many localities have recycling initiatives that can take corrugated items, and many of which are actually being followed.

7. Custom Corrugated Boxes

Custom corrugated boxes are used in a way that helps businesses promote their brand and get required packaging.

Advantages of Custom Designs

In the case of custom boxes, the boxes can be made to fit the products, therefore there is no need for a lot of padding. Also, it can have specific designs that correspond to the brand image and thus differ from others on the shelves and during transportation.

Printing Techniques

There are several ways that printing on custom boxes can be done including flexography and digital. Flexography is suitable for high volume production, but digital printing is more suitable for short-run production.

Success Stories

Most brands have benefitted from custom corrugated boxes and enhanced their packaging strategies. For example Apple and Coca Cola industries have employed new designs to ensure the best unboxing experiences to customers.

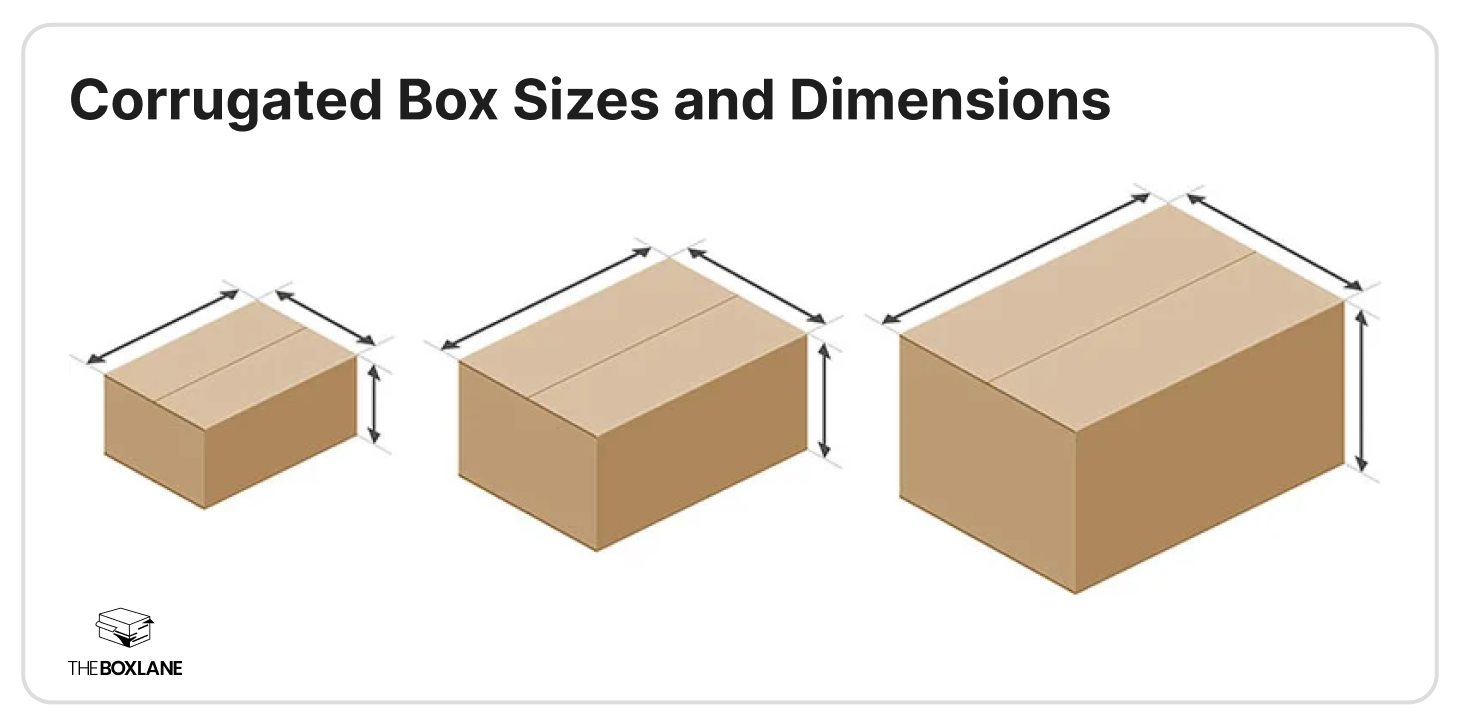

8. Corrugated Box Sizes and Dimensions

It is important to have some knowledge about the sizes of various boxes so as to meet the proper shipping and storage needs.

Common Standard Sizes

Many sizes of corrugated boxes are available but the following are common sizes used throughout the industry. These include:

- 12” x 12” x 12”

- 16” x 16” x 16”

- 24” x 24” x 24”

Custom Sizing Options

In the case of specialty products, a number of manufacturers allow for custom measurements. This means that businesses can easily get the right fit of the items they want to pack hence increasing the efficiency of packing.

Why Size Matters

Choosing the right size of a box means that the item inside gets to move very little in transit and thus has low chances of being damaged. Furthermore, it helps to minimize shipping costs by making the best of the available space in a shipping container or vehicle.

9. Shipping with Corrugated Boxes

It is imperative to ship products securely so that the clients will not stop purchasing from the business.

Best Practices for Packing Items Securely

- Choose the correct size of boxes that are to be used in shipping those items.

- Include padding particularly on delicate items.

- Use strong packing tape to seal boxes in a way that will not allow boxes to open during transit.

Labeling and Handling Instructions

Correct labeling of packages is very important so that those who come across packages know how to handle them. Specify definitive information for breakable goods together with any special usage guidelines.

Shipping regulations

Get acquainted with the current and past regulations and restrictions concerning the shipment of goods for international delivery. This includes customs documentation and labeling for an easy acquisition during transportation.

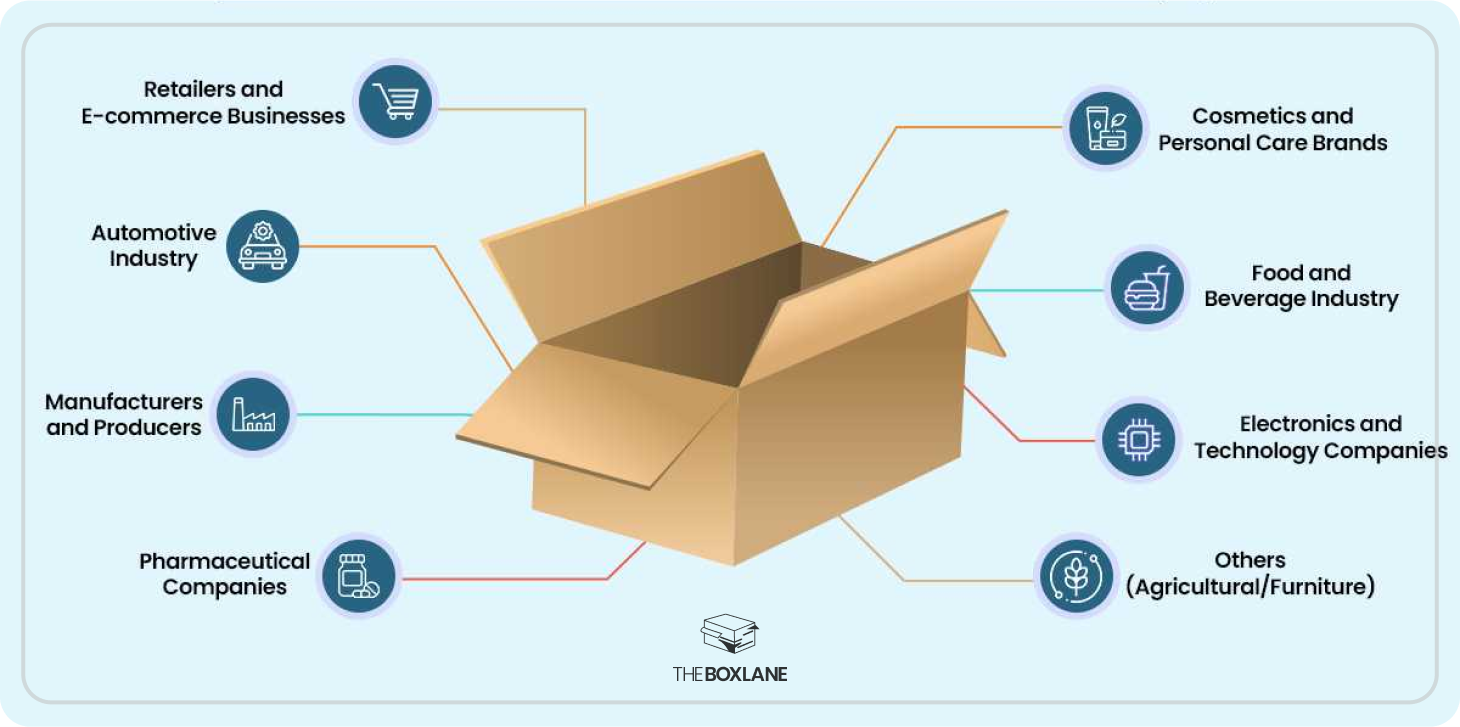

10. Application of Corrugated Box Across Industries

Corrugated boxes are useful to different industries which proves their effectiveness.

E-Commerce and Retail

Thanks to the e-commerce business, corrugated boxes are very popular among online sellers. They provide a secure method of delivering goods straight to the door of the consumer while reinforcing the image of the company.

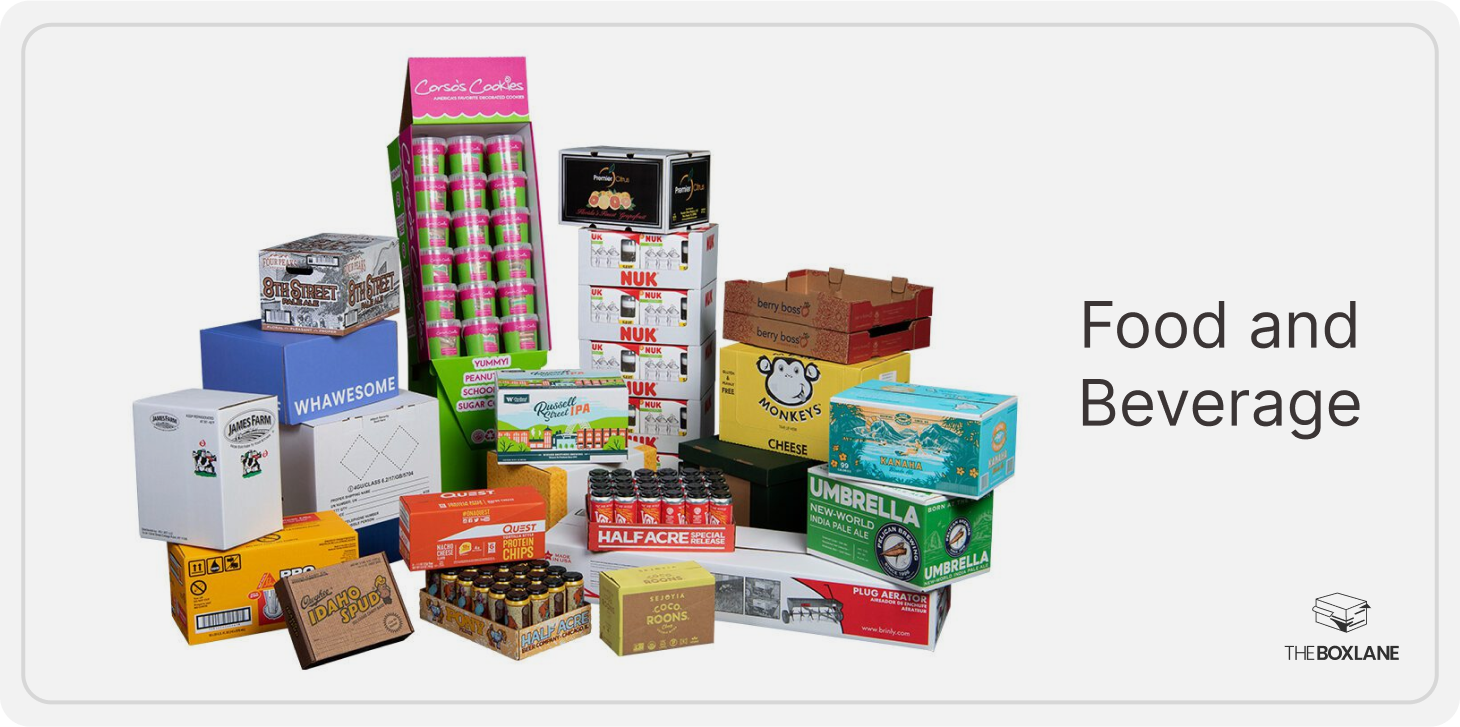

Food and Beverage

Most food manufacturers use corrugated boxes to transport food products that may become spoiled quickly. Due to their strength and flexibility in handling temperatures they are suitable for this sector.

Electronics and Fragile Items

The electronics manufacturing companies use corrugated boxes to pack delicate products for transit. Extra protection in the form of custom inserts can also be included.

Industrial and Logistics Applications

In the industrial sector corrugated boxes are employed in all types of machinery parts as well as in bulk items. Their strength enables them to move products safely.

Conclusion

Corrugated boxes are an important segment of packaging and distribute various advantages such as strength, versatility, and environmental friendliness. Since organizations are always in a constant search for efficient and affordable packaging material, the use of corrugated boxes will therefore rise.

At The Box Lane, we consider the selection of proper packaging to be a critical factor for your business. We also provide standard dimensions as well as bespoke designs depending on the client’s needs and preferences. Learn more about our corrugated boxes and find out how we can meet your packaging requirements.