In the dynamic and ever changing pharmaceutical business, packaging is an important factor in maintaining product integrity, quality and regulatory conformity. Flexible packaging has gained significant importance over the years because of the features such as flexibility, durability and compliance with most of the standards. This guide focuses on the increasing importance of flexible packaging in the pharmaceuticals field, advantages, new developments, and trends in this sector. From manufacturers, distributors, to the healthcare professionals, this guide will provide a wealth of information as to what flexible packaging is all about.

Understanding Flexible Packaging

Definition and Types of Flexible Packaging Used in Pharmaceuticals

Flexible packaging therefore means any packaging material made from flexible films or laminates. In pharmaceuticals they are used mostly in primary packaging, where they come into direct contact with the product, and in secondary packaging for large packaging or packaging of several items. Examples include:

- Blister packs: Used for single portions of tablets or capsules.

- Pouches: Popular with liquids, powders, or small equipment such as thermometers.

- Rollstock: It is used in packing bulky volumes of pharmaceutical products.

- Films and laminates: Employed in various forms as packaging material such as sachets and tubes.

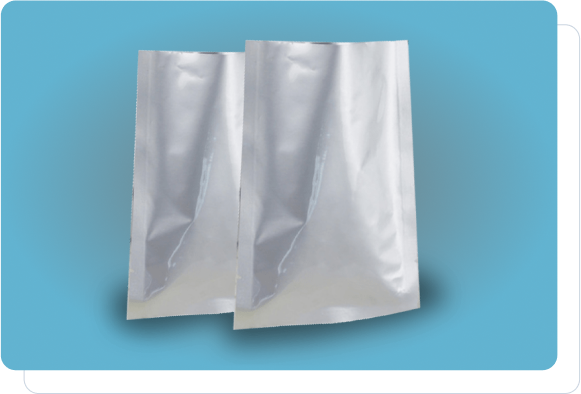

Comparison with Traditional Rigid Packaging Solutions

Conventional inflexible packaging, including glass containers or metal containers, has been applied for many years to protect pharmaceutical products. However, flexible packaging is gaining favor due to its many advantages:

- Weight and Cost Efficiency: Flexible packaging is portable, and its costs of transportation are low due to its lighter weight, hence a low carbon footprint.

- Customization: There is high flexibility because of size, shape and design variations from the regular clothes.

- Space Efficiency: Compared to rigid packaging, flexible packaging is relatively compact when it is stored and when it is being shipped.

On the other hand, some protection packaging, though more durable and protective, might be heavier and more expensive than the plastics; it also occupies more space for storing.

Main advantages of flexible packaging

Durability and Protection

Flexible packaging outperforms in providing the required endurance and shield to the products. Pharmaceutical products, especially those that are sensitive to environmental factors such as moisture, light, or air, benefit from the barrier properties of flexible materials. Packaging solutions such as blister packs and vacuum-sealed pouches help maintain the integrity of the product from manufacturing through to the end-user. This protects active ingredients, extending shelf life and preserving efficacy.

Adaptability

Flexible packaging can accommodate a wide range of pharmaceutical forms, from solid tablets to liquids, powders, and gels. This adaptability is crucial for pharmaceutical companies that produce diverse products. The flexibility in design ensures that packaging can be tailored to suit various product sizes and doses, providing convenience for both manufacturers and consumers.

Sustainability

As sustainability becomes an increasing priority, flexible packaging is stepping up to meet these demands. Many flexible packaging solutions are made from recyclable and biodegradable materials. By switching to eco-friendly materials, pharmaceutical companies can reduce their environmental footprint while still ensuring that the packaging meets all functional and safety requirements. Sustainable packaging solutions, such as recyclable blister packs or biodegradable films, are gaining traction in the industry.

Regulatory Compliance and Standards

Overview of Global Regulatory Requirements for Pharmaceutical Packaging

Pharmaceutical packaging has to conform to certain regulations as this packaging material comes into direct contact with the product. Many packaging materials and labeling and safety characteristics are controlled by the regulatory agencies like the FDA in the United States and the EMA in Europe.

These regulations include the necessity of material compatibility with the product formulation, accurate provision of labeling information, and tamper evident features to help prevent contamination of the product.

Guidelines to Follow When Dealing with Agencies Such as, the FDA and EMA

To ensure regulatory compliance, pharmaceutical companies must:

- Use certified materials: Materials used in packaging should conform to the requirements of the relevant authorities and should be trialled for safety.

- Incorporate tamper-evident features: The packaging should contain labels that can denote that it has been opened or tampered with; For instance, use of seals or breakable caps.

- Include clear labeling: The information that must be placed on the labels should include, but not be limited to dosage, ingredients, storage information and any special warnings as is recommended by FDA or EMA.

New ideas in flexible packaging material

Smart and Innovative Packaging

The new flexible packaging in the modern world has come up with two categories of packaging known as active packaging and intelligent packaging. These are such as moisture control sachets, oxygen absorbers and temperature check labels among others that are used in the packaging and hence enhances the shelf life and patient safety. Active packaging helps in protecting the medication from the environment while on the other hand intelligent packaging gives information of the product at that particular time.

Biodegradable and Recyclable Materials

Owing to the pervasiveness of plastics, the pharmaceutical industry is now on the lookout for new biodegradable and recyclable material for flexible packaging. Pharmaceutical packaging with biodegradable films, biodegradable pouches and biodegradable laminates are gradually being incorporated into the pharmaceutical packaging system as firms look for eco friendly packing material as opposed to the conventional plastic based packing materials.

Designing for Patient Adherence

Features That Improve Ease of Use and Compliance

Patient compliance with the dosages of the prescribed medications is greatly influenced by the packaging techniques. There are several features of flexible packaging that makes it easier for patients to get to their medication, including;

- Easy-to-open designs: Easy opening for the packages particularly for elderly or disabled patients.

- Clear labeling: Visible, intelligible, and instructive instructions on the package that assist a patient in the proper usage of a specific medication.

- Single-dose packaging: Ready to use single dose packs that will help avoid confusion and prevent medication misadventures.

Case Studies Demonstrating Successful Patient-Centric Packaging Designs

There is a growing trend where companies incorporate patient-centered packaging solutions. As one example, unit-dose blister packs are used to package oral medications. Apart from facilitating the process of identifying the daily doses for the patients, these packs also help to minimize contamination and also provide the best dosage ever.

Effect on the Supply Chain Performance

Ways on How Flexible Packaging Enhances Storage and Transportation

Flexible packaging has especially great advantages for the pharmaceutical supply chain. Due to its small size, it occupies little storage space, is easily space-saved, and consequently costs less to transport. Flexible packages are less likely to be broken during handling and transportation, therefore pharmaceutical companies benefit from it.

Cost Aspects and Advantages for Manufacturers and Distributors

Flexible packaging is known to have many benefits and one of them being reduced costs of packaging for pharmaceutical manufacturers and distributors. Flexible packaging materials are normally lighter and less bulky than other forms of packaging, which saves money on freight charges, in addition to being more resistant to causing damage to products en-route. Furthermore, flexible packaging also results in quicker production cycle time and enables the manufacturer to respond better to the market fluctuations.

Flexible Pharmaceutical Packaging – The Future Trends

Predicted Developments and Technologies Shaping the Industry

Smart packaging is expected to continue as a major trend in the future of pharmaceutical packaging, with track-and-trace capabilities enabling pharmaceutical firms to track the state of their product en route to the consumer. Smart packaging will also include advanced technologies like the NFC and RFID which can be used for tracking, authentication and security.

The Role of Sustainability and Digitalization in Future Packaging Solutions

Since sustainability is still a focal point, the need for innovative and digitalised environmentally friendly packaging materials and designs will persist. The use of environment friendly materials, digital printing for customization of packaging and data packaging will transform pharmaceutical packaging in the future.

Conclusion

Pouch packaging is gradually emerging as a preferred choice for pharmaceutical packaging because it is robust, versatile, and environmentally friendly. It offers manufacturers, distributors and healthcare facilities with solutions that are cheap, effective and eco-friendly. In the future, the future of the pharmaceutical packaging industry will depend on the adoption of new material technologies and new state and federal regulations. Pharmaceutical flexible packaging solutions can help the industry to satisfy the customer wants as well as reduce the impact of its production on the environment and the economy.