Modern business success depends heavily on the way companies package their products for the market. Flexible packaging, together with rigid packaging, emerges as the dominant packaging format in the market. Businesses must understand these distinctions because they need to select solutions that match their product specifications as well as sustainability requirements and financial capabilities. This blog examines flexible and rigid packaging contrasts through an examination of their benefits and drawbacks, along with recommendations for different industrial sectors.

Understanding Flexible Packaging

Flexible packaging consists of solutions that transform their dimensions both during filling operations and manual contact. Devices made from thin flexible films and laminates, and foils serve as the basis for these materials. The common flexible packaging formats include pouches together with bags, wrappers, in addition to sleeves. Flexible packaging demonstrates natural flexibility, which allows it to accommodate a diverse range of products under one package.

The Pros and Cons of Flexible Packaging

The main advantages of flexible packaging include its flexibility benefits. Flexible packaging achieves its most valuable benefit through cost efficiency. The manufacturing expenses decrease when producers use flexible packaging since these methods require lower materials and energy resources. A major benefit of its light weight structure enables reduced shipping expenses while cutting down fuel consumption when moving products. The market demand for sustainable flexible packaging strategies continues to increase. Product waste reduction is achievable through flexible packaging since manufacturers can implement features such as resealable closures as well as optimize product sizes. The customizable nature of this packaging technology enables businesses to design personalized packages with different shapes plus different sizes, as well as printer options, which strengthens their brand presence.

However, flexible packaging also has its drawbacks. While advancements in materials have improved durability, they generally offer less physical protection compared to rigid packaging, potentially making it less suitable for fragile items.

Is Flexible Packaging Eco-Friendly?

The rising environmental concerns about packaging matter have become an important issue for both businesses and their customer base. The common belief that plastic-based flexible packaging harms the environment proves incorrect because scientists now advance sustainable materials. Lower material requirements, along with weight reduction in flexible packaging, lead to reduced carbon emissions during its manufacturing process as well as transportation. The market is currently seeing increased interest in developing both biodegradable flexible packaging solutions and plastic-free flexible packaging alternatives. Efforts to recycle flexible packaging meet resistance from material layers in certain flexible packages. Various organizations work to build better recycling systems while developing flexible packaging methods that enhance recyclability. Flexible packaging represents an environmentally positive alternative, even though its implementation involves certain hurdles, provided manufacturers select sustainable materials across its lifecycle.

Exploring the Materials of Flexible Packaging

Flexible packaging incorporates a wide assortment of materials which provide unique characteristics during application. Three common types include:

- Plastic Films: The combination of plastic films dominates the market because they deliver exceptional versatility together with barrier protection and affordable cost. The packaging materials consist of polyethylene (PE) alongside polypropylene (PP) and polyethylene terephthalate (PET).

- Aluminum Foil: Aluminum Foil stands out due to its exceptional ability to block moisture and oxygen, and light, which makes it necessary for food product shelf life extension.

- Laminates: Laminates unite various materials into separate layers to achieve unique characteristics such as stronger structures, moisture barriers, and printing functions.

Understanding Rigid Packaging

Rigid packaging represents a firm structural design that keeps its dimensions unchangeable because of its stronger construction. Bottles, jars, cans, boxes, and cartons are among the typical items that belong to the rigid packaging category. The packaging design includes multiple material layers that both enhance product security and create an upscale appearance.

The Pros and Cons of Rigid Packaging

The main benefits of rigid packaging appear through its remarkable durability attributes which support product protection functions. Its firm structure stands strong against compression and impacts, and external forces, which means the contents stay protected, particularly when dealing with breakable or delicate objects. The packaging solution stands as the top selection when products need protective measures for shipping. Rigid packaging provides outstanding branding opportunities because it maintains detailed designs with high-quality prints that contribute to luxury brand aesthetics.

The expense of rigid packaging becomes higher because it requires greater materials during production, along with complicated manufacturing techniques. Rigid vs. flexible packaging cost and shipping expenses rise because of its heavier weight.

Key Differences Between Flexible and Rigid Packaging

Flexible packaging differs from rigid packaging because of form variations and flexibility qualities. Flexible packaging adopts different shapes and operates independently from its original form, but rigid packaging maintains a permanent structure. This essential distinction affects multiple other functional characteristics.

- Cost: Flexible packaging shows lower expenses both for manufacturing materials and production costs.

- Weight: Lighter flexible packaging properties help reduce transportation expenses because of their weight reduction.

- Protection: Rigid packages function better than flexible packages in providing protective measures against damage.

- Sustainability: Flexible packaging products need less material yet present difficulties in recycling. The recyclability of rigid packaging reaches high levels through the use of glass and aluminum materials.

- Branding: The two packaging methods deliver opportunities for brand representation, yet rigid packaging tends to create a deluxe brand perception.

- Space Efficiency: The storage requirements of flexible packaging decrease when it becomes empty, thanks to reduced packaging dimensions.

The Impact of Flexible Packaging on Shipping Costs

The lightweight character of flexible packaging leads to reduced shipping costs. Businesses, including e-commerce operators, benefit from owning flexible packaging because it results in reduced shipping expenses and lower delivery prices from carriers, thus providing a cost-saving packaging solution.

Industries Commonly Using Flexible Packaging

Flexibility in packaging material allows its usage in various sectors such as:

- Food Industry: The food industry utilizes flexible packaging to cover snacks and confectionery products, frozen meals & beverages, and food-grade flexible packaging for retail products.

- Consumer Goods: For detergents, personal care products, and household items.

- Pharmaceuticals: Flexible packaging serves the pharmaceutical sector through high-barrier films for medications as well as vacuum-sealed packages for ensuring sterility.

- Pet Food: The manufacturing of pet food requires bags and pouches that contain both dry and wet products.

Industries Commonly Using Rigid Packaging

The use of rigid packaging appears in multiple business sectors at the same time.

- Beverage Industry: For bottles and cans of drinks.

- Food Industry: The food industry uses jars and bottles as well as rigid cardboard solutions for packaging sauces and jams and cereals.

- Cosmetics and Personal Care: The cosmetics and personal care industry requires bottles, jars, and compacts for creams, lotions, and makeup products, which typically need rigid packaging solutions.

- Pharmaceuticals: Rigid containers serve pharmaceutical purposes by protecting bottles and vials that require pharmaceutical specifications with tamper-proof features.

- Electronics: Electronics require boxes together with containers, which provide shipping and retail protection.

How Rigid Packaging Provides Better Product Protection

The inherent strength and fixed form of rigid packaging offer superior protection against physical damage. Packages consisting of glass and metal, and thick plastics work as effective barriers by protecting against damage from impact and crushing during shipment and packaging. Fragile items and products require particular protection through rigid packaging because they need to endure tough supply chain handling throughout the packaging process.

Is Rigid Packaging More Recyclable Than Flexible Packaging?

The ability to recycle packaging depends firstly on the materials used and secondly on existing recycling facilities in the region. Flexible packaging poses recycling challenges because of its layered structure, but PET and HDPE materials remain among the recyclable elements. The recycling rates of rigid materials such as glass and aluminum stand particularly high because these materials have well-developed recycling systems. The recyclability status of PET plastic rigid containers and similar rigid materials tends to be widespread throughout various regions of the world.

What are the Environmental Benefits of Flexible Packaging?

The environmental benefits of flexible packaging exist even though it presents some recycling obstacles. The decreased amount of material used in flexible packaging results in reduced extraction of natural resources and decreased energy requirements throughout production. The packaging weight reduction helps vehicles use less fuel, which results in decreased greenhouse gas emissions during transport. The progress of environmentally friendly packaging trends has prompted manufacturers to create better sustainable flexible packaging solutions.

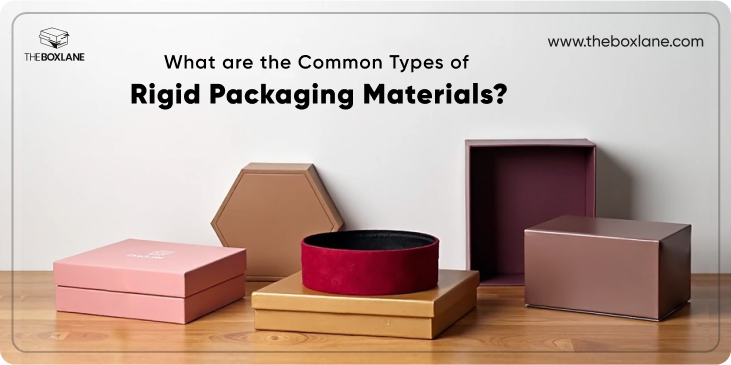

What are the Common Types of Rigid Packaging Materials?

Different materials form rigid packaging through their distinct features, which determine their properties:

- Glass: Food benefits from both stellar protection barriers and complete recyclability through glass materials.

- Metal (Aluminum and Steel): Both Aluminum and Steel materials give strong protection and can achieve high levels of recyclability.

- Plastics (PET, HDPE, PP, PVC): Plastic materials, including PET, HDPE, PP, and PVC, show versatility and maintain decent barriers, but their recyclability levels differ.

- Paperboard and Cardboard: Boxes and cartons frequently use paperboard and cardboard since they deliver excellent structural stability alongside printability and typically qualify for recycling.

How Does Packaging Choice Affect Consumer Perception?

The packaging decision between flexible and rigid elements determines the way consumers view a product. Rigid packaging materials transmit an impression of premium quality while delivering durability and high value, which makes them appropriate for luxury or high-end products. Flexible packaging delivers convenience and lightness, and sometimes shows sustainability features that appeal to customers focused on practicality and environmental awareness. The proper packaging selection must match the brand identity, together with the mental picture that customers have about the product.

What are the Latest Trends in Flexible and Rigid Packaging?

Modern flexible and rigid packaging developments follow several ongoing advancements and new trends.

- Sustainability Focus: Increased demand for recyclable, compostable, and bio-based materials in both flexible and rigid formats.

- Lightweighting: The reduction of material usage coupled with weight minimization in both packaging types serves two goals: it decreases environmental impact and it reduces shipping expenses.

- Smart Packaging: Integration of technologies like QR codes, NFC tags, and sensors for enhanced traceability, consumer engagement, and product safety.

- Customization and Personalization: The market demands personalized custom printing on packaging because companies want their branding to match customer preferences.

- Minimalist Design: Simplistic packaging designs have become popular because they present both functional and sustainable aspects in minimalist forms.

Conclusion

Companies must carefully choose between flexible and rigid packaging options as part of their business operations. Flexible packaging dominates commercial use because it lowers costs and allows product weight reduction, yet increases sustainability opportunities. Rigid packaging stands superior in protecting contents and establishing luxurious branding. Knowledge of flexible and rigid packaging distinctions with their positive and negative points helps businesses determine the package that suits their specific needs, financial limitations, and sustainability targets best. Organizations make strategic decisions that strengthen their business outcomes through thorough evaluation of product breakability combined with shipping requirements, along with brand messaging and customer perception.