Flexible packaging serves as the driving force behind frozen food industry changes. The packaging system incorporates plastic films together with foil and paper, which enable bending and folding capabilities. Such packaging functions unlike traditional rigid containers. The correct flexible packaging gives frozen food products extended freshness and safety features, and convenient usability benefits. The article presents an explanation of how flexible packaging functions while demonstrating its significance to business operations and outlining company advantages.

Why Frozen Food Packaging Matters?

The correct packaging method serves as a vital requirement for products that need to be frozen. Freezing stops bacterial growth, but food still needs protection. The absence of proper packaging allows freezer burn to combine with moisture loss and contamination, thereby destroying product quality. The tight barrier produced by flexible packaging allows for proper closure. It blocks air and moisture. The packaging design enables longer preservation of food while extending its shelf life. The implementation of such packaging solutions simplifies the operation of cold chain logistics systems. The use of lightweight packaging methods helps companies save shipping expenses and decreases their disposal waste. Food safety packaging protects the product from factory production facilities until the consumer places it in their freezer.

The Preferred Materials Used for Frozen Food Packaging

Frozen food packaging materials directly influence the quality outcomes of frozen products. The packaging materials polyethylene (PE) and polypropylene (PP) demonstrate excellent flexibility for packaging purposes. Cold storage packaging conditions do not affect their strength and flexibility. Barrier protection during storage becomes possible with the addition of laminated bag layers. These block oxygen, moisture, and light. Vacuum-sealed bags eliminate air from the packaging to block freezer burn development. The retort pouch proves suitable for frozen meal packaging because it withstands high heat and freezing temperatures. Multiple food-compatible packaging solutions safeguard both quality and durability of products.

The Requirements of Frozen Food Products

Different frozen food products belong to the industry sector. Each type needs specific packaging. Frozen vegetable and fruit packaging needs to maintain product moisture content as well as texture integrity. Boundary protection materials are essential for meat and seafood items to prevent spoilage while preserving their taste. The packaging solutions for ready-to-eat meals include convenient packaging, which allows quick heating of frozen dinners and pizzas. Desserts that include ice cream and pastries require packaging with temperature resistance to resist cold conditions while protecting themselves from damage. Flexible containers incorporate resealable pouches to meet customer requirements.

Key Factors in Choosing Frozen Food Packaging

The process of choosing appropriate packaging includes defined procedures. The first requirement of packaging protection methods is to block oxygen and moisture, and light exposure to preserve quality. Extreme cold conditions require materials that maintain their durability during storage without breaking. The convenience of consumers plays a vital role in packaging choices since they need easy-to-open features such as resealable pouches. Sustainable packaging stands as a vital consideration among the other points. Green consumers prefer frozen food packaging that employs sustainable materials which are either recyclable or biodegradable. Finally, cost matters. The choice of flexible packaging wins the rigid packaging vs flexible packaging matchup due to lower material requirements and lower shipment expenses. These factors guarantee that food storage solutions fulfill both business requirements and customer needs.

How to Create Custom Frozen Food Packaging?

Companies possess the ability to create their customized packaging solutions. The process is simple. Start with packaging design. Expert collaboration enables you to develop a custom packaging design that matches your company brand along with its merchandise. Companies should select their flexible packaging materials based on requirements, including thermal properties or protective barriers. Printing the design with clear branding details through high-quality printing methods completes the process. The trusted manufacturer will finish the packaging production. The packaging requirements must fulfill all food-grade standards. Companies achieve uniqueness through customized packaging solutions that create specialized frozen food packaging designs.

New Trends in Flexible Packaging

The industry keeps improving. New packaging solutions enhance the quality of frozen foods available for market consumption. The company YutoEco introduced FluoZero, which uses plant materials as its base. This material can endure temperatures between -34°C and 220°C, which makes it suitable for cold storage containers and cooking needs. Sustainable packaging is growing popular too. Compostable films cut environmental impact. The addition of smart features such as QR codes enhances product value. Flexible packaging systems help consumers through their convenience design, which enables them to store their unused portions. Modern consumer need to find their solution through the adaptive nature of flexible packaging solutions in the frozen food industry.

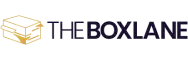

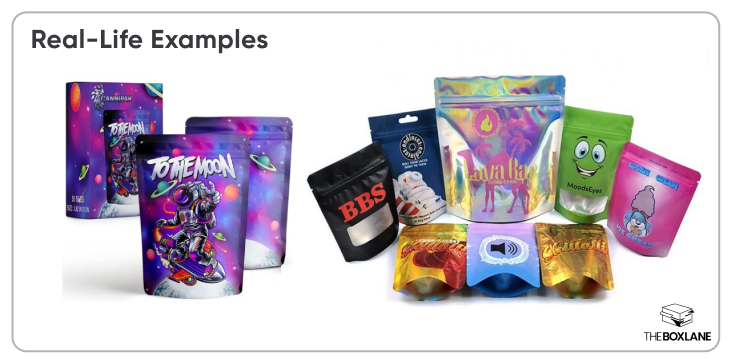

Real-Life Examples

Companies prove that flexible packaging works. Birds Eye, as a major frozen food company, implements resealable pouches to package their vegetable products. Users remove their required amount and preserve the remaining portion. This approach decreases waste while providing better convenience to consumers. Schwan’s implements vacuum-sealed bags to preserve meats. Sealed bags protect the contents from freezer burn and preserve original taste. The packaging analyst Jane Smith from FoodTech Solutions emphasizes that flexible packaging provides brands with market advantages. Practical design complements food safety packaging to create this solution. Research demonstrates that sealing technology in frozen food products leads to business achievements.

Facts Backing Flexible Packaging

Data supports its value. Flexible packaging stands out from rigid packaging solutions because it requires only 75% of the material needed, according to the Flexible Packaging Association. This cuts costs and waste. According to Frost & Sullivan research conducted in 2022, 60% of consumers prefer resealable pouches for their frozen goods. Planetary weight reduction designs afford cold chain logistics providers the potential for cost savings reaching up to 20%. The data demonstrates why flexible packaging remains the top choice in the market.

Why It Works

The frozen food industry benefits from flexible packaging through multiple obvious advantages. The material creates a protective barrier that also stops freezer burn damage. Throughout the extended shelf life and food preservation process, the packaging acts as a support mechanism. The packaging solutions delivered by this method are both convenient and durable. When considering the price and adaptability ratio, flexible packaging outperforms rigid packaging. Businesses achieve financial savings through packaging strategies that fulfill consumer requirements. The selection of environmentally friendly packaging solutions follows sustainability targets.

Final Thoughts

Flexible packaging introduces a revolutionary method of handling frozen foods production. The packaging material protects items from harm and maintains freshness, together with usability. Companies like Birds Eye and Schwan’s show its real-world impact. The implementation of temperature-resistant packing with sustainable materials allows the technology to fulfill modern consumer needs. Applications of flexible packaging need evaluation for frozen meals and additional products by businesses. Businesses make a sound decision to choose flexible packaging for frozen food because it yields premium-quality products with efficient processing while propelling market development.