Flexible, sleek, and often eco-friendly, these packages don’t just hold the product; they tell a story, offer convenience, and sometimes even protect the planet. Did you know that flexible packaging makes up nearly 60% of the global packaging market and is expected to grow by 4.5% annually until 2028?

So, here’s a question for you: What if the packaging you choose could elevate your brand, extend product shelf life, and reduce waste all at once? Whether you’re in the food industry, pharmaceuticals, or even e-commerce, flexible packaging is the unsung hero revolutionizing how products are delivered to consumers.

In this blog, we’ll unravel the types of flexible packaging, materials, films, and everything else you need to know to make informed decisions in 2025. Let’s dive in!

Types of Flexible Packaging

Flexible packaging is revolutionizing industries with its versatility, cost-effectiveness, and eco-consciousness. Let’s dive deeper into the most popular types of flexible packaging, their applications, and what makes them a game-changer in 2025.

Pouches

Pouches are the heroes of modern packaging. With their sleek design and high functionality, they’ve become a favorite across various industries.

-

Types of Pouches:

Stand-Up Pouches: These are excellent for products like soups, sauces, snacks, and even pet food. They are designed to stand upright on shelves, offering excellent visibility and reducing storage space.

Flat Pouches: Commonly used for single-serving items like instant coffee, spices, or cosmetic samples, flat pouches are compact and lightweight.

Gusseted Pouches: These are designed for bulkier products like coffee, grains, and tea. The gusset expands, allowing the pouch to hold more volume.

-

Consumer-Friendly Features:

Many pouches come with resealable zippers, tear notches, or spouts for convenience, making them ideal for on-the-go lifestyles.

Their lightweight nature significantly reduces shipping costs and carbon emissions.

-

Eco-Friendly Appeal:

The growing demand for recyclable and biodegradable materials is driving innovation in pouch designs, making them a sustainable choice for brands.

-

Fun Fact:

The global stand-up pouch market is projected to reach $35 billion by 2025, fueled by their lightweight, sustainable, and convenient designs.

Bags

Flexible bags have been a staple in industries for decades, offering simplicity and practicality for a wide range of products.

-

Types of Bags:

Flat-Bottom Bags: These combine the stability of a box with the flexibility of a bag, making them ideal for coffee, flour, and sugar.

Pillow Pouches: Often used for snacks like chips and cookies, pillow pouches are economical and easy to produce.

-

Why They’re Popular:

They are versatile and customizable, with ample space for branding.

Their durability ensures that products stay fresh and protected during transportation.

-

Sustainability Twist:

Many companies are switching to compostable or biodegradable flexible bags to meet consumer demand for eco-friendly packaging.

These materials break down naturally, reducing their impact on the environment.

Sachets and Stick Packs

Compact, lightweight, and resource-efficient, sachets and stick packs are ideal for single-serving needs.

-

Applications:

Sachets: Often used for condiments, shampoos, or pharmaceutical products.

Stick Packs: Perfect for powders, energy drinks, or sugar.

-

Why Consumers Love Them:

Their portable and single-serve nature makes them convenient for busy lifestyles.

They use minimal material compared to traditional packaging, contributing to reduced waste.

-

Eco-Friendly Edge:

Many manufacturers are now offering recyclable or compostable options, appealing to eco-conscious consumers.

Wraps and Sleeves

Flexible wraps and sleeves are perfect for products that need secure yet visually appealing packaging.

-

Applications:

Wraps: Commonly used for bakery items, candies, and chocolate bars. Their tight seal ensures freshness and protection.

Sleeves: Frequently seen on bottles, jars, or bundled products. They’re designed to fit snugly around items, often with eye-catching branding.

-

Why They’re Gaining Popularity:

Shrink sleeves offer 360-degree branding opportunities, making them a favorite for beverages and cosmetics.

They are lightweight and reduce material usage compared to rigid labeling options.

Blister Packs

While traditionally associated with rigid packaging, blister packs also have flexible variants.

-

Key Features:

Flexible blister packs combine a layer of aluminum or other barrier materials with flexible films, offering excellent protection against moisture, light, and contamination.

They are commonly used for pharmaceuticals like tablets and capsules.

-

Why Industries Rely on Them:

They offer a tamper-proof seal, ensuring product safety.

Flexible blister packs are lighter and more economical than rigid versions, reducing transportation and production costs.

Flexible Cans

Flexible cans are a modern marvel, providing the same functionality as traditional metal cans but with lightweight materials.

-

Applications:

Popular for soups, pet food, ready-to-eat meals, and beverages.

-

Why They Stand Out:

They mimic the durability and protective qualities of metal cans while being easier to transport and store.

Flexible cans significantly reduce production and shipping costs due to their lightweight structure.

-

Eco-Friendly Advantage:

Many flexible cans are designed to be recyclable or use renewable materials, aligning with sustainability goals.

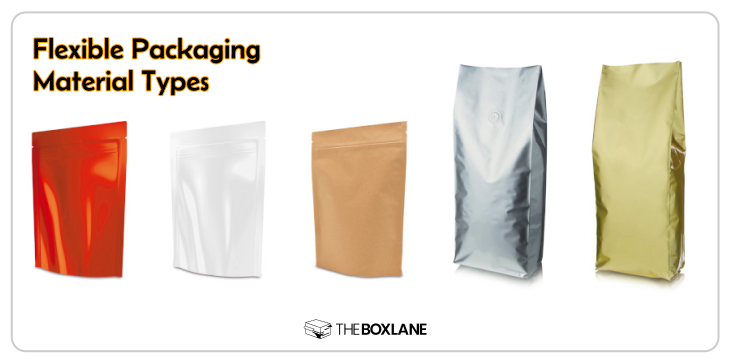

Flexible Packaging Material Types

Understanding the materials used in flexible packaging is key to leveraging their unique benefits. Here's a deeper dive into the most popular materials and their applications:

Bioplastics

Bioplastics are revolutionizing the packaging industry by offering an eco-friendly alternative to traditional plastics.

-

What Are Bioplastics?

Derived from renewable resources like corn, sugarcane, or potato starch, bioplastics can be biodegradable, compostable, or recyclable.

Common types include Polylactic Acid (PLA) and Polyhydroxyalkanoates (PHA).

-

Applications:

Used for food packaging, single-use items, and even agricultural films.

PLA is often seen in items like flexible pouches, shopping bags, and sachets for its low carbon footprint.

-

Sustainability Spotlight:

The use of bioplastics in packaging is expected to grow at a CAGR of 16% by 2025, driven by consumer demand for sustainable products.

These materials break down into natural components, reducing landfill waste and environmental impact.

Polymer Films

Polymer films dominate the flexible packaging world for their durability and adaptability.

-

Key Types:

Polyethylene (PE): Includes both high-density and low-density variants, offering flexibility and toughness.

Polypropylene (PP): Known for its clarity, moisture resistance, and excellent barrier properties.

-

Advantages:

Lightweight yet strong, making them ideal for products ranging from snacks to electronics.

Customizable barrier properties ensure protection against oxygen, moisture, and light.

-

Popular Applications:

Food wraps, pouches, sachets, and vacuum-sealed bags rely on polymer films for their performance and cost-effectiveness.

-

Eco Innovations:

Advances in polymer technology have led to the development of recyclable and bio-based polymer films, contributing to sustainability goals.

Corrugated Cardboard

When combined with flexible films, corrugated cardboard offers unmatched protection for heavier or bulkier items.

-

What Is a Corrugated Cardboard?

Made from fluted paper sandwiched between two linerboards, it’s lightweight yet robust.

-

Applications in Flexible Packaging:

Used as part of hybrid packaging solutions for e-commerce shipments, bulk goods, and fragile items.

Often paired with plastic liners or films to provide additional barrier protection.

-

Eco-Friendly Edge:

Fully recyclable and biodegradable, making it a favorite for sustainable packaging solutions.

Perfect for brands looking to balance strength with eco-conscious practices.

Aluminum Foil

Aluminum foil is a staple in flexible packaging due to its superior barrier properties.

-

Why It’s Essential:

Blocks out moisture, light, and air, preserving product freshness and extending shelf life.

Thin and lightweight yet strong, making it ideal for compact packaging.

-

Applications:

Commonly used in food packaging (e.g., chocolate wraps, coffee bags) and pharmaceutical products like blister packs.

Its reflective surface also adds a premium look to product designs.

-

Sustainability Efforts:

Though not biodegradable, aluminum foil is infinitely recyclable, making it a sustainable choice when properly disposed of.

Kraft Paper

Kraft paper is a go-to material for brands looking to combine eco-friendliness with simplicity.

-

What Is Kraft Paper?

A durable paper made from chemical pulp during the kraft process, known for its strength and natural brown color.

-

Applications:

Frequently used for bakery bags, coffee pouches, and minimalist product wraps.

Its versatility extends to eco-friendly mailers for e-commerce brands.

-

Eco-Friendly Features:

Fully recyclable and biodegradable.

Many brands use kraft paper with plant-based coatings for added barrier protection while maintaining sustainability.

-

Why Consumers Love It:

Offers a rustic, authentic aesthetic that aligns with natural or organic product branding.

UV Protective Films

UV protective films are critical for products sensitive to sunlight and UV exposure.

-

What Are UV Protective Films?

Thin, flexible films designed to shield products from harmful UV rays that can degrade quality or alter composition.

-

Applications:

Widely used in cosmetics, pharmaceuticals, and beverages, particularly for products displayed under direct lighting.

Ideal for outdoor packaging or items with extended shelf lives.

-

Advantages:

Protects product integrity and appearance by preventing discoloration or spoilage.

Enhances the shelf life of sensitive products like serums, vitamins, or light-sensitive beverages.

-

Sustainability Note:

New developments include UV films made from recyclable materials, addressing both performance and environmental concerns.

How to Choose the Best Flexible Packaging Type?

Selecting the ideal flexible packaging for your product isn’t just about wrapping it up—it’s about meeting specific needs while ensuring functionality, aesthetics, and sustainability. Here’s a deeper dive into the key factors that influence this decision:

Product Type: Liquid, Solid, or Powdered?

The nature of your product is the first determinant in choosing the right packaging. Liquids, such as juices or soups, require leak-proof options like spouted pouches or flexible cans to ensure no spillage during handling and transport. Solid products, ranging from snacks to detergents, may need packaging with high durability and strength, such as flat-bottom bags or stand-up pouches. Powdered items, like protein mixes or spices, demand moisture-resistant packaging with excellent seal integrity to maintain freshness and prevent contamination.

Shelf Life: Does It Need High Barrier Protection?

Products with extended shelf life requirements—such as perishable foods, pharmaceuticals, or coffee—need packaging with high barrier protection to block out oxygen, moisture, and light. Materials like BOPP, BOPET, and laminates are excellent choices for such applications. For products with shorter shelf lives, simpler and more cost-effective options like LDPE or Kraft paper bags may suffice. Evaluating your product’s storage and transportation conditions is critical to ensuring its longevity and quality.

Sustainability Goals: Biodegradable or Recyclable Materials?

With consumers increasingly prioritizing eco-friendly choices, your packaging must align with sustainability goals. If your brand aims to minimize environmental impact, options like Kraft paper, bioplastics, or BOPE can offer compostable or recyclable solutions. Flexible packaging made from mono-materials is particularly gaining traction, as it simplifies the recycling process. Balancing sustainability with functionality is key—choosing materials that meet eco-standards without compromising on product protection.

Consumer Convenience: Is Resealability a Priority?

Modern consumers demand convenience in every aspect of product usage. Resealable packaging, such as pouches with zippers or spouts, is highly sought after for products that are consumed over time, like pet food, coffee, or snacks. Easy-to-open features, portability, and ergonomic designs also play a role in enhancing the consumer experience. Consider the preferences of your target audience to determine whether convenience-focused features are necessary for your packaging design.

Brand Aesthetics: Does the Design Align with Your Branding?

Packaging is a powerful tool for brand storytelling, and its design should reflect your brand’s identity. High-quality printing on flexible packaging materials like BOPP or laminates allows you to showcase vibrant graphics, logos, and product information effectively. For eco-conscious brands, minimalist designs using Kraft paper or bioplastics can resonate with environmentally aware customers. Whether it’s a sleek, modern look or a rustic, earthy feel, ensure that your packaging aligns with your brand’s ethos while standing out on the shelves.

When you carefully evaluate these factors, you ensure that your packaging not only protects and preserves your product but also appeals to consumers and aligns with your business goals. In today’s competitive market, flexible packaging is as much about functionality as it is about creating an emotional connection with your customers.

Printing Options for Flexible Packaging

Digital Printing

Perfect for small runs and customization, digital printing offers quick turnaround and high-quality graphics without the need for printing plates, making it ideal for limited editions or personalized packaging.

Flexographic Printing

Best for large-scale production, flexographic printing is fast, cost-effective, and provides excellent results on various materials. It's ideal for products like snack bags and pouches, where high-volume printing is needed.

Rotogravure Printing

Known for its ability to produce intricate, high-quality designs, rotogravure printing is used for premium packaging, especially for luxury products. Though it has higher setup costs, it delivers superior results for large production runs.

Sustainable Printing

Water-based and soy-based inks are eco-friendly alternatives, offering a safer, more sustainable option for printing flexible packaging without compromising on quality. Ideal for brands prioritizing sustainability.

Conclusion

Flexible packaging in 2025 isn’t just about holding products; it’s about telling a story—of innovation, sustainability, and consumer convenience. From pouches to polymer films, the possibilities are endless. With the right materials, types, and printing techniques, your packaging can transform your product's shelf appeal and align with modern trends.

Ready to take your packaging to the next level? The Box Lane offers customizable and innovative flexible packaging solutions tailored to your needs. Explore the future of packaging with us today!