Flexible packaging appears everywhere in the world through snack pouches, coffee bags, and cosmetic sachets. The packaging format is highly popular because it remains lightweight and affordable while being adaptable for brands and consumers. Creating flexible packaging designs comes with various challenges that should not be underestimated. Designers must manage various important aspects, which include avoiding print cracking and making products stand out on retail shelves. This article provides you with functional guidelines to create perfect flexible packaging designs. Let’s get started!

What Is Flexible Packaging?

We should first understand the topic at hand before continuing with the tips. Materials categorized as flexible packaging consist of plastic films along with pouches and wraps that experience movement without breaking. The main feature of flexible packaging lies in its capacity to adapt. Flexible packaging stands out as a revolutionary solution because the Flexible Packaging Association identifies it as the key to efficiency and sustainability.

Why Design Matters in Flexible Packaging?

Business success through design goes beyond superficial beauty since it transforms your brand identity. Research indicates that customers make 70% of their buying choices at retail stores when they first encounter packaging products (Paper and Packaging Board). A cracked logo or distorted text? Quickly losing customer trust becomes inevitable when such mistakes happen. The design of flexible packaging stands essential because current trends emphasize sustainable materials and practical features. Therefore, you need perfect design execution. Here’s how to do it right.

Essential Tips for Flexible Packaging Design

1. Choose the Best Materials

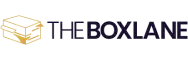

Material selection for flexible packaging is the base for your product development. Chosen materials properly ensure both long-lasting durability and prevent visual print-breaking defects. Popular options include:

- PET (Polyethylene Terephthalate): Flexible, strong, and great for printing.

- Polypropylene: Tough and resistant to moisture—perfect for snacks.

- Laminated Films: Combine layers for added strength and barrier properties.

Standalone aluminum foil should be avoided because it cracks easily unless it is laminated. The selection of packaging materials should correspond to your product requirements such as moisture protection for foods and cosmetic durability to develop workable designs.

2. Master Your Printing Techniques

Flexography represents a difficult printing process for flexible materials. Your flexible packaging requires printing methods that ensure both attractive and long-lasting visual outcomes. Two top methods:

- Flexography: Fast, affordable, and ideal for large runs. The printing method proves suitable for various flexible materials according to Printing Industries of America.

- Digital Printing: Offers high-definition precision for bold, intricate designs.

The choice of ink should match your material well because weak bonding results in material separation or loss of design integrity. Print cracking prevention depends on this technique because it maintains design integrity even under intense motions.

3. Simplify Your Design

For successful flexible material design, it is essential to keep designs simple. Flexible packaging will change shape due to movement, which can break down small text or cause it to become deformed. Here’s the fix:

- Big logo sizes and large textual elements will produce outstanding results.

- Smooth round edges should replace pointy corners for a better design.

- The color scheme should remain fresh and avoid overcrowding the design elements.

Your brand recognition increases simultaneously with issue prevention through this approach, hence enhancing consumer appeal for packaging designs.

4. Test Rigorously

Testing is your safety net. Carry out rigorous tests that duplicate ordinary product usage by twisting and folding along stretching motions. Testing your design through this method allows you to detect any early signs of damage to your packaging solutions. Rework your design alterations or change materials whenever detection of problems are detected. Identifying problems with custom packaging solutions in advance becomes more beneficial than waiting until they reach customers.

Advanced Strategies to Stand Out

Embrace Sustainable Packaging Design

The term sustainability stands as more than just market jargon because it represents an absolute requirement. Consumer demand for sustainable packaging has surged to the extent that 66 percent of consumers will spend extra money to support companies offering environmentally friendly options (Nielsen). Opt for:

- Recyclable materials like PET.

- Biodegradable films for a green edge.

- Reduce shipping emissions through lightweight product designs.

The Environmental Protection Agency shows that companies moving to flexible packaging reduce their CO2 emissions dramatically thus delivering environmental and economic benefits.

Boost Branding in Flexible Packaging

The branding of your product should be obvious through the design. A product becomes memorable when it uses the boldest colors combined with clear logos and coordinated designs. Packages that present clear designs will always perform better than cluttered ones. A packaging design with practical features, including zippers or easy-open tabs, will provide functionality that encourages customer loyalty.

Stay Compliant with Regulations

Regulatory compliance in flexible packaging must be strictly followed by companies working in the food, pharma, and cosmetics sectors. Manufacturers must review FDA regulations together with local requirements that specify labeling protocols and material standards, and safety requirements (FDA). The failure to complete this step can cause your launch to fail; thus, you need to ensure every detail is complete.

Real-World Example: A Snack Pouch Win

The company launched its new chips in a stand-up pouch design. The company selects PET because of its ability to stretch while being resistant to moisture and pairs this material with flexography printing technology to achieve clear lettering in a straightforward design. They perform additional testing on the ink through flex testing before making required adjustments to prevent future cracking. The result? The protective pouch maintains both strength and attractiveness for product defense. The process of creating flexible packaging for market success involves these guidelines.

The Data Behind the Success

Why does this matter? Flexible packaging solutions reduce transportation expenses by 75% as opposed to alternative rigid packaging formats Flexible Packaging Association. The packaging method helps products last longer while working to reduce the 1.3 billion tons of food waste in the U.S. each year (USDA). Good design offers dual advantages of being both beautiful to look at and productive for profit and functions.

Bringing It All Together

Flexible package design stands as both a scientific practice and an artistic expertise. Your flexible packaging design starts with selecting premium materials and then adds precise printing methods, together with simplicity and multiple tests. The combination of sustainable packaging design elements with strong flexible packaging branding, together with strict adherence to standards, will lead to business success. Your flexible packaging designs will achieve excellence through these guidelines, regardless of whether you develop snacks or cosmetics.

Want to upgrade your packaging? Implement these ideas now because both your customers and your financial performance will benefit.