Eligible orders produced in 10 business days or less 📦 Save 20% On Your First Order +

Corrugated gable boxes are sturdy. They are good for the planet and for heavier items. Use it for gifting, giveaway packaging, or to pack anything that you want to look special. Start with a free custom sample today

CMYK

Emboss & Deboss

Foiling

Matte or Gloss

Metalized Printing

PMS

Screen Printing

Velvet Touch Finish

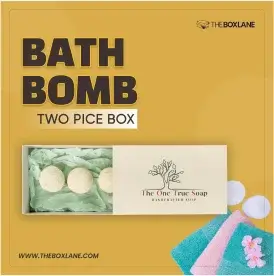

Corrugated gable boxes are made with eco-friendly corrugated material. The box style is gable which has beautiful gable-like sides and a handle for easy carry.

The value of corrugated gable boxes is that these are strong boxes. They can be used for heavier products like cakes, bigger gifts, etc. The mere fact that these are gable adds style to your custom packaging and giveaway boxes.

Like all custom packaging, corrugated gable packaging creates immense value for a brand.

Use a fully customized corrugated box for your product packaging to improve brand value, enrich brand image, connect with the planet-caring segment of your audience, and earn free word-of-mouth marketing for your brand.

When you design it right, people will share it on social media, especially Instagram, and you will get free marketing.

Here is why you should buy corrugated gable boxes for product packaging, gifts, or giveaways.

Proper customization brings in a real return for your custom packaging investment. We offer all-around customization for product boxes.

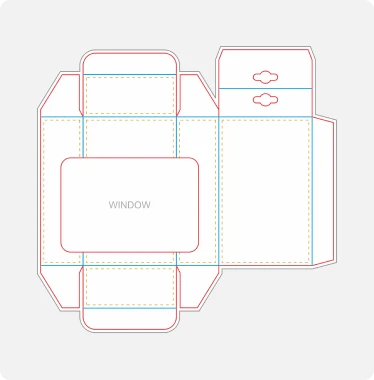

For every product packaging, customization starts with box style. A corrugated cardboard gable box is a fine choice for products, gifts, and giveaway packaging. Let’s explore other ways to personalize the looks and construction of corrugated cardboard gable boxes.

Start with the material. You can choose the different thickness and weight of the corrugated material.

Corrugated material offers a lot of choice for customization. Get your corrugated box with an outer layer of cardboard. This corrugated cardboard combines the strength of corrugated with the fine finish and lovely look of cardboard.

Popular packaging printing methods include offset printing, digital printing, screen printing, and gravure printing.

Use these guidelines to prepare artwork for custom packaging. You can also get help from our in-house design team and make sure that the artwork perfectly matches your vision. We are just one click away.

Shows final size line, all artwork and design must be kept inside with a margin of 0.125 inches for perfect printing.

Bleed line is the limit to where design and artwork can be extended.

Shows where the packaging will be folded.

Indicate line with small punches for easier and precise tearing.

Shows the limit for artwork and test, the safety margin is 0.125 inch for perfect printing.

01/04

The order process starts when you request a free quote or place your order via email, phone, chat, or website contact form. You can reach us in many ways and place an order. You give us information about quantity, design, size, material, and finishing and we start processing your order.

02/04

When we receive details of your order, we contact you to confirm the packaging design and artwork. We work with you to finalize box designs and artwork and once everything is just as you want it to be, we confirm your order for production.

03/04

Confirmed orders go to production which takes fewer days than the competition. We take only 8-10 days for expedited orders and 15-18 days for regular orders. You get updates as we progress on your order.

04/04

We run a quality assurance process before we ship your order. We offer shipping that you can track all the time and be sure that your goods are on their way to you.

We offer premium white cardboard stock in 16pt-24pt thickness, there is no limit on printing colors.

Kraft stock is a brown, eco-friendly, recyclable material that is available in 16pt-24pt thickness range.

Hard, shock-absorbing material, also called e-flute, corrugated stock is the go-to material for shipping boxes.

Thickest available material for cardboard packaging, Rigid stock is available in 1000 gsm-1900 gsm weight.

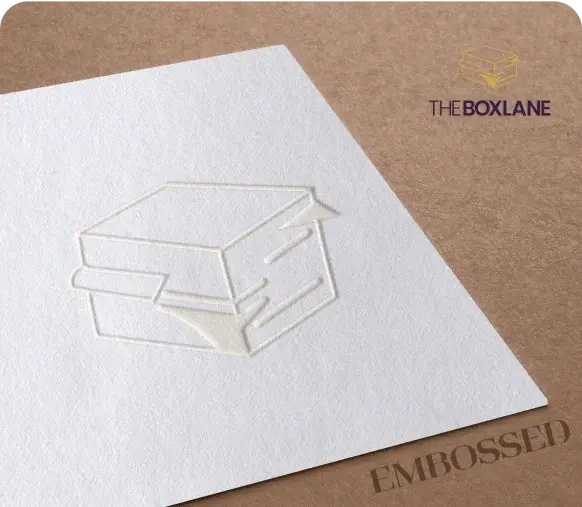

Embossing is the technique of lifting an image or text a little off the surface to highlight it.

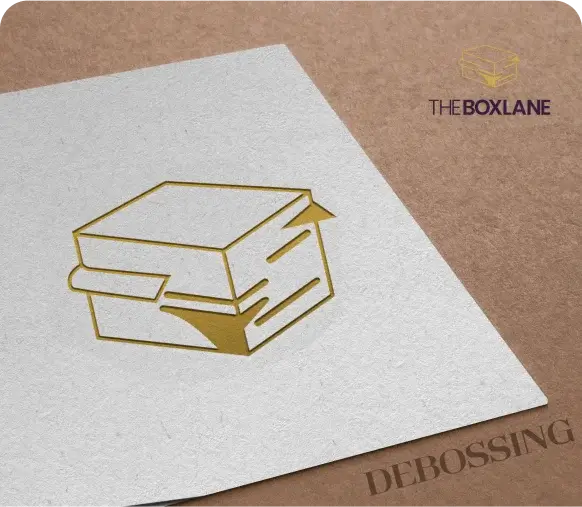

Debossing is the printing technique that suppresses the text or image.

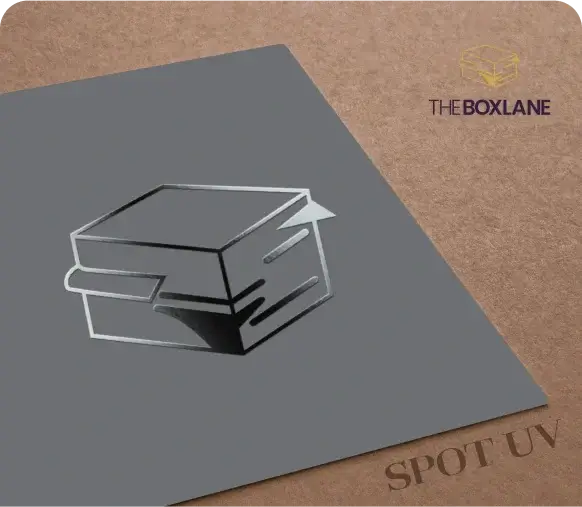

Spot UV coating gives more gloss and shine to an area that you want to highlight.

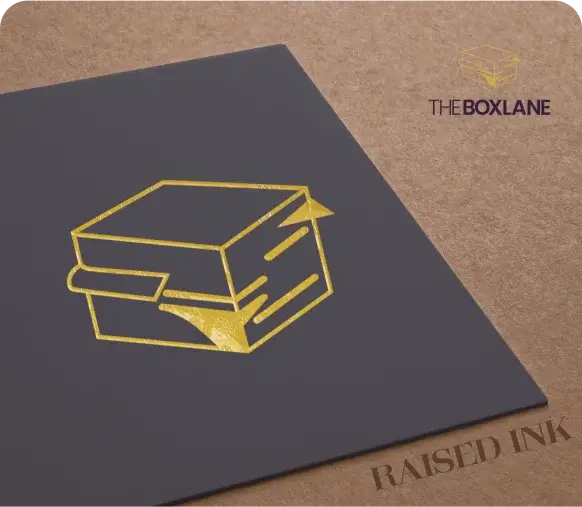

Raised ink gives text a raised and shiny look that brings an impression of luxury.

Holographic foiling helps focus the gaze on the specific area by playing with color variation with angle change.

We turn customers into fans with our dedication, product quality, and support. Read what some of our fans have to say about The Box Lane.

These are some of the repeated questions we get. Ask us on WhatsApp or Chat if we missed something.