Eligible orders produced in 10 business days or less 📦 Save 20% On Your First Order +

Custom toy packaging is an important part of branding for toys. It protects toys, gives a glimpse into the product, and entices customers to buy the product. Reform toy packaging for your brand. Start with a free sample today.

CMYK

Emboss & Deboss

Foiling

Matte or Gloss

Metalized Printing

PMS

Screen Printing

Velvet Touch Finish

Custom toy packaging saves toys from transit damage or any other harm and shows your brand on it very well.

You will also be required to use personalized toy boxes by law as many toys have small parts and there is a choking hazard for little babies and kids.

We know custom packaging is more than just housing of the product. It helps with branding, and it also earns you free marketing. Retail packaging is a prime example of that.

Among retail packaging, custom packaging influences toys even more. How? Because both the buyer and consumer are involved in the process. The kid that will use the toy and the adult who will pay for that look at the toy, its packaging, and its price, and then decide if they will buy that toy.

To please both involved parties, get fully custom toy boxes.

When you build bespoke packaging for a brand, you are sure to improve its perceived value. The same is the case with toys.

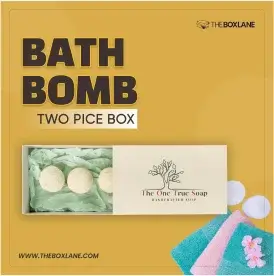

The kind of box we use for toy packaging depends on the toy’s size and type. Tuck boxes, open flap boxes, larger drawer or sleeve boxes, gable boxes, rigid boxes, and magnetic boxes, all are apt for toy packaging. However, a transparent window is a must in every toy box.

A toy is inspected by both the kid and the parent. A brand can’t let everyone touch the toy or it will be dysfunctional in a day.

The solution to that problem is adding a transparent window so that people can see the toy without opening the box.

Cardboard is the default material. Kraft stock is the most cost-effective. Rigid boxes give an air of luxury, use them if toys are priced high. Corrugated boxes work perfectly as mailer boxes and toy shipping boxes.

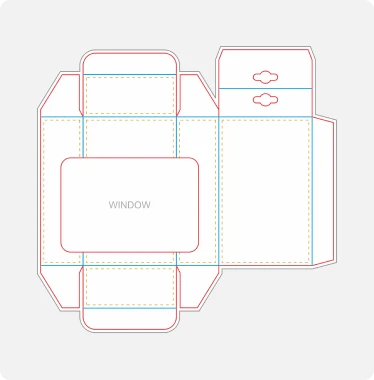

Use these guidelines to prepare artwork for custom packaging. You can also get help from our in-house design team and make sure that the artwork perfectly matches your vision. We are just one click away.

Shows final size line, all artwork and design must be kept inside with a margin of 0.125 inches for perfect printing.

Bleed line is the limit to where design and artwork can be extended.

Shows where the packaging will be folded.

Indicate line with small punches for easier and precise tearing.

Shows the limit for artwork and test, the safety margin is 0.125 inch for perfect printing.

01/04

The order process starts when you request a free quote or place your order via email, phone, chat, or website contact form. You can reach us in many ways and place an order. You give us information about quantity, design, size, material, and finishing and we start processing your order.

02/04

When we receive details of your order, we contact you to confirm the packaging design and artwork. We work with you to finalize box designs and artwork and once everything is just as you want it to be, we confirm your order for production.

03/04

Confirmed orders go to production which takes fewer days than the competition. We take only 8-10 days for expedited orders and 15-18 days for regular orders. You get updates as we progress on your order.

04/04

We run a quality assurance process before we ship your order. We offer shipping that you can track all the time and be sure that your goods are on their way to you.

We offer premium white cardboard stock in 16pt-24pt thickness, there is no limit on printing colors.

Kraft stock is a brown, eco-friendly, recyclable material that is available in 16pt-24pt thickness range.

Hard, shock-absorbing material, also called e-flute, corrugated stock is the go-to material for shipping boxes.

Thickest available material for cardboard packaging, Rigid stock is available in 1000 gsm-1900 gsm weight.

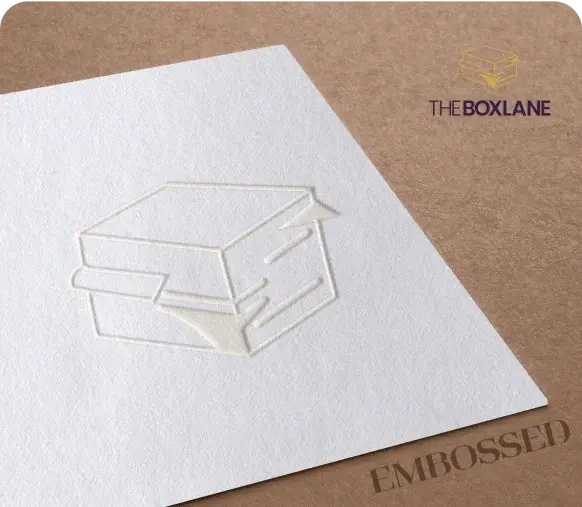

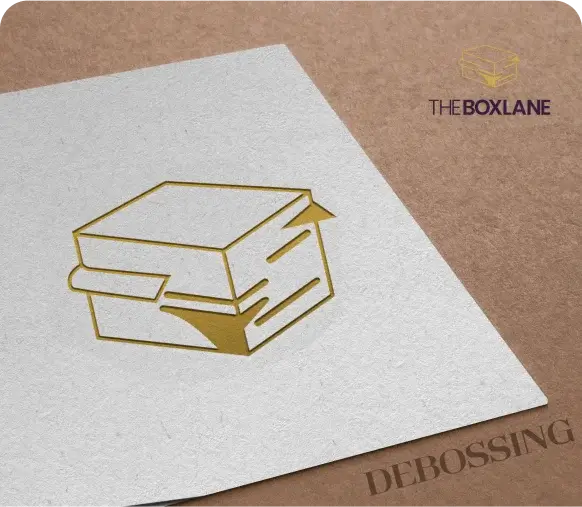

Embossing is the technique of lifting an image or text a little off the surface to highlight it.

Debossing is the printing technique that suppresses the text or image.

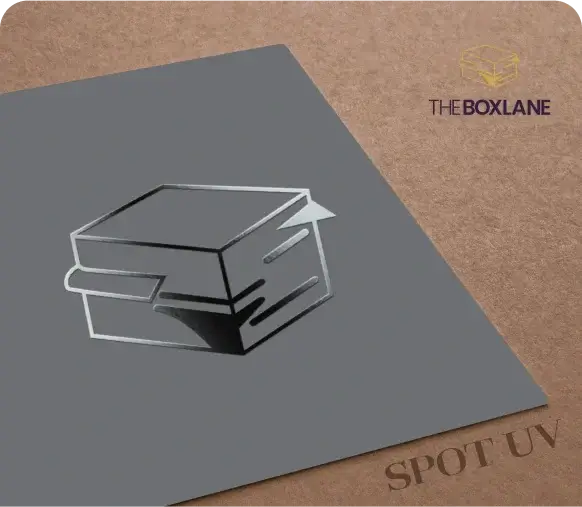

Spot UV coating gives more gloss and shine to an area that you want to highlight.

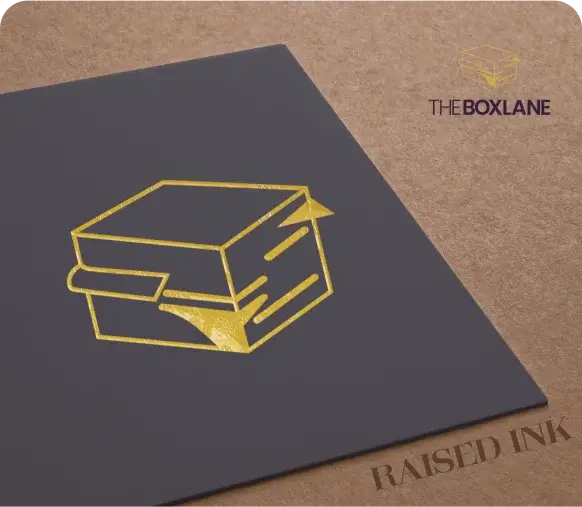

Raised ink gives text a raised and shiny look that brings an impression of luxury.

Holographic foiling helps focus the gaze on the specific area by playing with color variation with angle change.

We turn customers into fans with our dedication, product quality, and support. Read what some of our fans have to say about The Box Lane.

These are some of the repeated questions we get. Ask us on WhatsApp or Chat if we missed something.